|

||||||

Large Spring Manufacturing

Aeronautical • Agricultural • Medical • Automotive - Tier 1, Tier 2 and Tier 3

• Chemical •

Electronics • Energy • Food Processing • Gas & Oil

HVAC • Home Protection • Marine • Water Treatment

Order Form Downloads

Custom Spring Manufacturing

Prototypes to production

We can tackle the most simple of parts to the most complicated turn-key project.

Once again our team is excited about the opportunity to offer you a solution for your larger spring manufacturing issues. We have been bending, winding and shaping springs since 1968. We strive to be a consultative development support team that is competitively priced from prototyping through production.

- Spring Design and Manufacturing Consulting

- Design Prototyping

- Rapid Prototyping

- Research & Development

- Industry Standard Software Spring Design Analysis

- Spring Design Drawings and Engineering

- Fatigue Testing

- Reverse engineering of existing samples

- Fast-Track quoting & delivery

We work with many different materials including:

- Music Wire

- Stainless Steel Type 302 and Type 17-7PH

- Beryllium Copper

- Phosphor Bronze

- Inconel

Processes available include:

- Coil

- Stress Relieve

- Grind

- Set Remove

- Passivate

- Tumble

Our team can provide an array of finishes to meet your design needs, including:

- Color Identification

- Corrosion protection

- Zinc Plate

- Phos & Oil

- Chromate Dip

- Passivate

- Shot Peen

- More...

Sample of Packaging Services Available Include

- Returnable Packaging

- Customer Supplied Containers/Totes

- Assembly Line Ready Arrangements

- Small Quantities in Plastic Bags

- Layer Packaging

- Tack Board

- More...

| Compression Springs |

|

||

|---|---|---|---|

| Extension Springs |

|

||

| Torsion Springs |

|

||

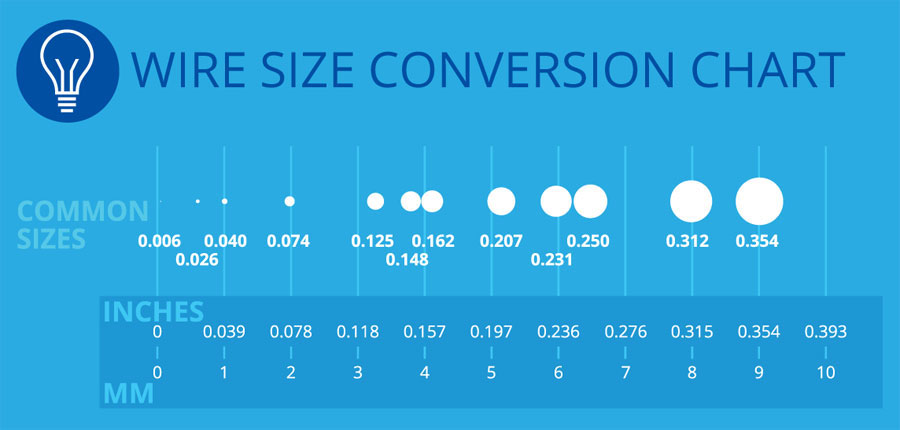

| Wire Forms | Shapes to suit Wire Diameter from 0.020” and up (0.5mm and up) |

||

| Tolerances | Commercial Tolerances Easily Met – Tight Tolerance Specialists | ||

| Equipment – Compression | CNC & Mechanical Coilers, Automatic Length Control and adjustment on all compression coilers. | ||

| Equipment - Extension | Up to 4 axis CNC coiling machines. Automatic probe systems for hook position control. | ||

| Equipment – Torsion/Wireforms | Up to 5 Axis CNC Torsion Spring Forming Machines. Automatic position control for accurate leg relationships. | ||

|

|||

Spring Design & Engineering ServicesOur team can support you every step of the way. Analysis of your blueprints combined with a clear understanding of your needs allows our spring design and engineering team to help you with everything from spring material selection and pricing, to manufacturability consulting. Our team uses industry standard Spring Design software. We can help you optimize your spring design in order to minimize your cost, and maximize the fatigue life of the spring. |

| General Capabilities |

|

||

|---|---|---|---|

| Capabilities | Industry Standard Software Spring Design Analysis Fatigue Testing Reverse Engineering |

||

| Design Assistance |

|

||

| Engineering Analysis | Failure Analysis Fatigue Life Prediction Fit-For-Use Analysis |

Need more information about our Stampings & Assemblies?

Please contact us at (561) 752-9095. Our highly skilled team of engineers and design technicians are ready to take on your most demanding Stampings & Assemblies projects from our prototyping services menu.